Upgrading your shower floor is a great way to enhance both the functionality and aesthetics of your bathroom. Using 2K synthetic resin for this task ensures durability, waterproofing, and a sleek finish. Follow this step-by-step guide to achieve a professional-quality shower floor that will stand the test of time.

Materials Needed

- Moisture Meter: To check the subsurface for moisture.

- Strength Tester: To assess the strength of the subsurface.

- Hammer or Mallet: For detecting hollow areas.

- Level: To check the slope of the subsurface.

- Milling Machine or Diamond Grinder: For preparing the subsurface.

- 2K Synthetic Resin: For creating the slope, leveling, priming, sealing, and wear layers.

- Roller: For applying the synthetic resin layers.

Step-by-Step Instructions

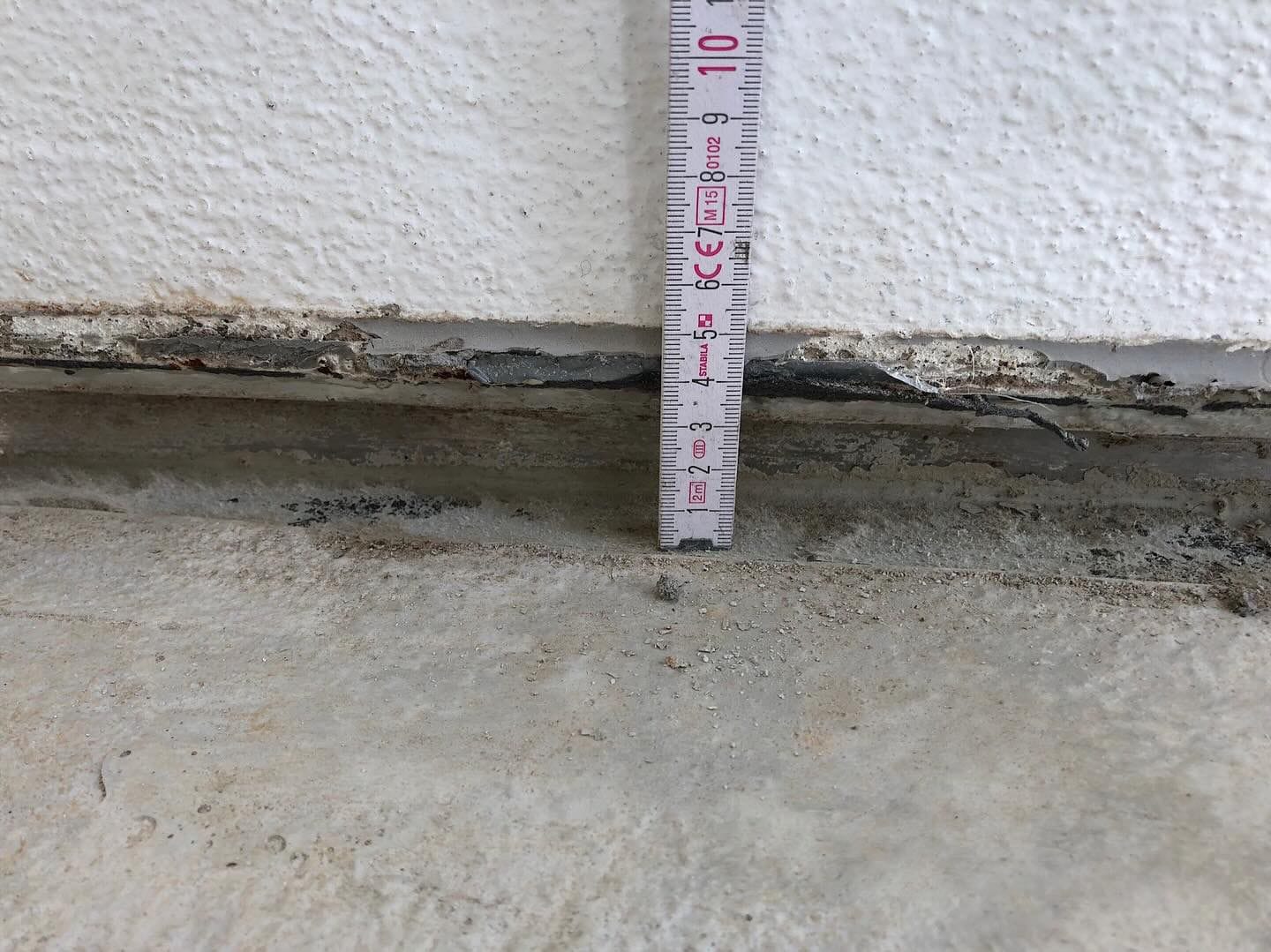

1. Checking the Subsurface

- Moisture Check: Use a moisture meter to ensure the subsurface is dry. Excess moisture can compromise the resin layers.

- Strength Test: Assess the strength of the subsurface. It should be solid and able to support the new flooring.

- Detect Hollow Areas: Tap the subsurface with a hammer or mallet. Hollow sounds indicate weak spots that need to be addressed.

- Check the Slope: Use a level to determine the existing slope. Proper drainage requires a slight slope toward the drain.

2. Preparing the Subsurface

- Milling or Diamond Grinding: Prepare the subsurface by milling or grinding to create a clean, rough surface that the resin can adhere to.

3. Creating the Slope or Leveling Unevenness

- 2K Synthetic Resin Application: If necessary, create a slope or level out uneven areas using 2K synthetic resin. This ensures proper water drainage and a smooth finish.

4. Applying the Primer

- Primer Layer: Roll on a primer layer made of 2K synthetic resin. This layer enhances adhesion for subsequent layers.

5. Sealing the Surface

- Seal Layer: Apply a seal made of 2K synthetic resin to waterproof the subsurface and provide an additional barrier against moisture.

6. Applying the Wear Layer

- Wear Layer: Apply a wear layer of 2K synthetic resin. This layer will endure the daily wear and tear of shower use, ensuring longevity.

7. Final Sealing

- Final Seal: Roll on a final seal made of 2K synthetic resin. This top layer provides extra protection and a polished finish.

Creating a durable and stylish shower floor with 2K synthetic resin is a manageable DIY project that offers professional results. By carefully preparing the subsurface and applying multiple resin layers, you ensure a strong, waterproof, and attractive finish. Follow these steps, and you’ll enjoy a beautiful shower floor that enhances your bathroom for years to come.

CREATOR: Esther

INSTAGRAM: @colognecountrylife

COMPANY: Brabender GmbH

INSTAGRAM: @brabendergmbh